Submersible sewage cutter stainless steel water pump

General Information

The Depon WQ Series SubmersibleSewage Pumps are electro submersible centrifugal pumps designed for pumping waste water, effluent and solids laden water in municipal, industrial, mining and civil construction applications.

Applications

Transfer of waste water, effluent and solids

laden water for:

• Water Treatment

• Building Services

• Sumps and Basements

• Mining

• Civil Construction

• Industry

• Municipal

• Processing

Technical Data:

Features:

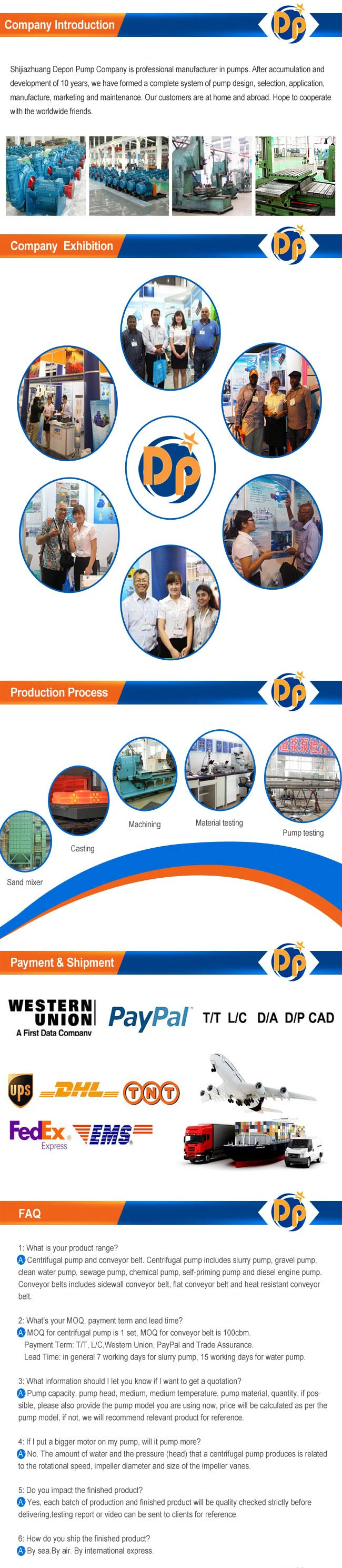

• High strength cast iron pump construction.

• Impeller options are available to suit a range of applications and pumped products including single, double or triple vane.

• 420 Stainless steel shaft.

• Built in cooling system allows operation when motor is submerged or above water level.

• Optional external cooling available.

• Cast iron replaceable neck ring insert.

• Class F motor insulation with maximum working temperature of up to 155°C.

• IPX8 motor protection.

• Dual mechanical seals with carbide/tungsten seal faces on pump side and graphite/silicon carbide faces on motor side provide effective sealing between motor and wet end.

• Mechanical seals are oil bath lubricated.

• Motor stator incorporates three shutdown temperature control sensors which automatically detects motor temperatures at 125°C.

• Oil chamber incorporates a water leakage probe which detects when water-to-oil ratio is too high and cuts off power to prevent motor damage due to oil contamination.

• Motor incorporates water detection sensor at the top and a float switch in the bottom to detect the ingress of water and cut power to prevent motor damage.

• Available with a wide range of protective coatings and paint options.

• Optional product grinders available on request.

• Optional automatic coupling device available to enable simple maintenance and servicing.

• Mild steel outlet pipe installation with flanged connections as standard.

• Optional soft outlet pipe installation available to allow quick and simple mounting and removal when required.

• Optional fixed dry installation available with external cooling water.

Materials

Conditions of use

1. Medium temperature should not be over 40degree, the density no larger than 1200kg/m, and the PH value within5-9.

2. During running, the pump must not be lower than the lowest liquid level.

3. The maximum diameter of the solid grain going through the pump has not be larger than 50% of the pump outlet.

Structures Description

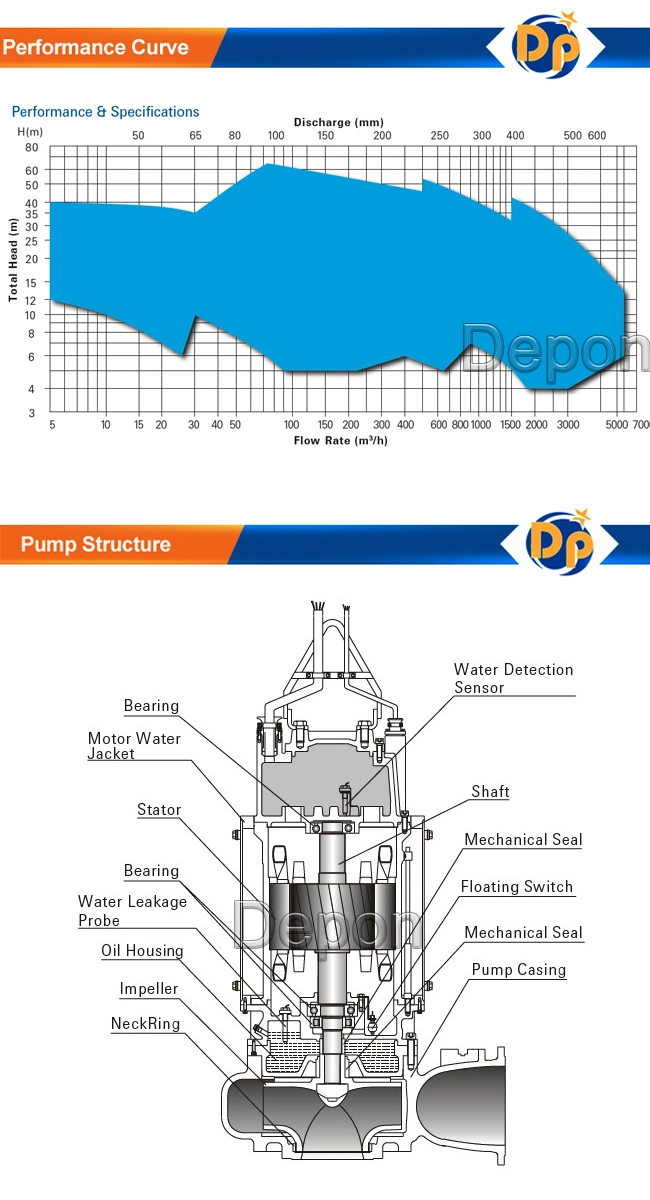

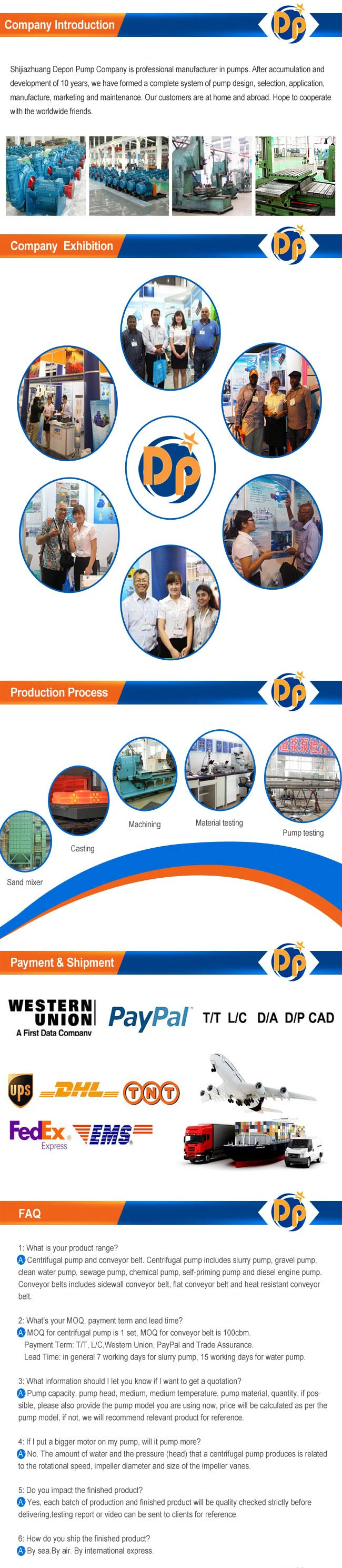

WQ Pump Performance

The above pump performance for reference only, details please contact us!

FAQ

A: What kind of company you are?

Q: Shijiazhuang Depon Pump Company is professional manufacturer in pumps. After accumulation and development of many years, we have formed a complete system of pump design, selection, application, manufacture, marketing and maintenance. We have passed CE, SGS certificate. Our customers are at home and abroad. Hope to coorperate with the worldwide friends.

Q: What's your MOQ?

A: Trial sample order is OK.

Q: What are your payment terms?

A: T/T, L/C, D/P, D/A or as customer required

Q: How about the warranty?

A: One year warranty for pumps, it depends on other pump working condition details.

Q: What is the delivery time?

A: 7-30 days according to customer quantities.

Q: Can you do OEM brand?

A: Yes, Welcome.

Q: What information should I offer to get pump solution?

1, Head: m

2, Flow: m3/h

3, Max Solid size: mm

4, Particle shape (smooth or sharp):

5, Medium pH level:

6,Specific Gravity of the Medium:

7, Temperature:

8, Drive type:

9. Power supply: Electric or Dlesel

10, Voltage and Frequency of the Motor:

Welcome inquiry!

Serena Zhang

Contact:

Mob: +86 158 3083 2057

Tel: +86 312 8929296

Fax: +86 312 3085383

General Information

The Depon WQ Series SubmersibleSewage Pumps are electro submersible centrifugal pumps designed for pumping waste water, effluent and solids laden water in municipal, industrial, mining and civil construction applications.

Applications

Transfer of waste water, effluent and solids

laden water for:

• Water Treatment

• Building Services

• Sumps and Basements

• Mining

• Civil Construction

• Industry

• Municipal

• Processing

Technical Data:

| Type | Centrifugal | Submersible | ||

| Medium | Sewage | Waste water | Rain water | Living water |

| Flowrate | Min.:10m3/h | Max.:6000m3/h | ||

| Head | Min.:7m | Max.:62m |

Features:

• High strength cast iron pump construction.

• Impeller options are available to suit a range of applications and pumped products including single, double or triple vane.

• 420 Stainless steel shaft.

• Built in cooling system allows operation when motor is submerged or above water level.

• Optional external cooling available.

• Cast iron replaceable neck ring insert.

• Class F motor insulation with maximum working temperature of up to 155°C.

• IPX8 motor protection.

• Dual mechanical seals with carbide/tungsten seal faces on pump side and graphite/silicon carbide faces on motor side provide effective sealing between motor and wet end.

• Mechanical seals are oil bath lubricated.

• Motor stator incorporates three shutdown temperature control sensors which automatically detects motor temperatures at 125°C.

• Oil chamber incorporates a water leakage probe which detects when water-to-oil ratio is too high and cuts off power to prevent motor damage due to oil contamination.

• Motor incorporates water detection sensor at the top and a float switch in the bottom to detect the ingress of water and cut power to prevent motor damage.

• Available with a wide range of protective coatings and paint options.

• Optional product grinders available on request.

• Optional automatic coupling device available to enable simple maintenance and servicing.

• Mild steel outlet pipe installation with flanged connections as standard.

• Optional soft outlet pipe installation available to allow quick and simple mounting and removal when required.

• Optional fixed dry installation available with external cooling water.

Materials

| Description | Standard Material | Material Options |

| Shaft | 420 Stainless Steel | |

| Pump Casing | Cast Iron | SS316/ Duplex |

| Impeller | Cast Iron | SS316/ Duplex |

| Neck Ring | Cast Iron | SS316/ Duplex |

| Motor Water Jacket | Mild Steel | SS316 |

| Motor Mechanical Seal | SS304 | |

| Wet End Mechanical Seal | SS304 | |

| Motor Body | Cast Iron | SS316 |

| Oil Housing | Cast Iron | SS316 |

Conditions of use

1. Medium temperature should not be over 40degree, the density no larger than 1200kg/m, and the PH value within5-9.

2. During running, the pump must not be lower than the lowest liquid level.

3. The maximum diameter of the solid grain going through the pump has not be larger than 50% of the pump outlet.

Structures Description

| Bearing | Imported and Local market brand |

| Cooling | Built-in cooling system |

| Motor | F class insulation, max. working temperature 155degree |

| Seal | Mechanical seal |

| Oil chamber | Oil can lubricate and cool the mechanical seal |

| Impeller | Optimized design |

| Pump casing | CAD/CAM design |

| Float switch | warning signal |

WQ Pump Performance

| Item | Type | Outlet diameter (mm) | Capacity (m3/h) | Head (m) | Speed (r/min) | Power (kw) | Efficiency (%) |

| 1 | 50WQ15-8-0.75 | 50 | 10-20 | 7-10 | 2825 | 0.75 | 52 |

| 2 | 50WQ15-16-1.5 | 50 | 10-20 | 10-18 | 2840 | 1.5 | 52 |

| 3 | 65WQ30-10-2.2 | 65 | 20-45 | 8-12 | 1420 | 2.2 | 62 |

| 4 | 65WQ30-35-7.5 | 65 | 20-45 | 30-37 | 1440 | 7.5 | 50 |

| 5 | 80WQ50-35-11 | 80 | 40-75 | 27-40 | 2900 | 11 | 55 |

| 6 | 80WQ50-40-15 | 80 | 40-75 | 37-42 | 2900 | 15 | 52 |

| 7 | 100WQ80-36-18.5 | 100 | 65-120 | 30-40 | 2900 | 18.5 | 55 |

| 8 | 100WQ80-40-22 | 100 | 65-120 | 35-45 | 2900 | 22 | 55 |

| 9 | 150WQ150-40-30 | 150 | 100-200 | 33-42 | 1470 | 30 | 65 |

| 10 | 200WQ400-27-45 | 200 | 250-500 | 24-35 | 1480 | 45 | 74 |

| 11 | 250WQ500-25-55 | 250 | 400-700 | 16-22 | 980 | 55 | 74 |

| 12 | 300WQ1000-20-75 | 300 | 800-1400 | 15-23 | 990 | 75 | 82 |

| 13 | 350WQ1100-25-110 | 350 | 900-1500 | 18-30 | 980 | 110 | 76 |

| 14 | 350WQ1500-40-250 | 350 | 1200-2000 | 33-42 | 740 | 250 | 80 |

| 15 | 400WQ2000-36-280 | 400 | 1500-2800 | 27-43 | 745 | 280 | 80 |

| 16 | 500WQ3000-11-132 | 500 | 2000-4000 | 8-14 | 745 | 132 | 75 |

| 17 | 600WQ4000-12-200 | 600 | 3000-6000 | 7-16 | 745 | 200 | 72 |

The above pump performance for reference only, details please contact us!

FAQ

A: What kind of company you are?

Q: Shijiazhuang Depon Pump Company is professional manufacturer in pumps. After accumulation and development of many years, we have formed a complete system of pump design, selection, application, manufacture, marketing and maintenance. We have passed CE, SGS certificate. Our customers are at home and abroad. Hope to coorperate with the worldwide friends.

Q: What's your MOQ?

A: Trial sample order is OK.

Q: What are your payment terms?

A: T/T, L/C, D/P, D/A or as customer required

Q: How about the warranty?

A: One year warranty for pumps, it depends on other pump working condition details.

Q: What is the delivery time?

A: 7-30 days according to customer quantities.

Q: Can you do OEM brand?

A: Yes, Welcome.

Q: What information should I offer to get pump solution?

1, Head: m

2, Flow: m3/h

3, Max Solid size: mm

4, Particle shape (smooth or sharp):

5, Medium pH level:

6,Specific Gravity of the Medium:

7, Temperature:

8, Drive type:

9. Power supply: Electric or Dlesel

10, Voltage and Frequency of the Motor:

Welcome inquiry!

Serena Zhang

Contact:

Mob: +86 158 3083 2057

Tel: +86 312 8929296

Fax: +86 312 3085383