1.1 Pump Introduction:

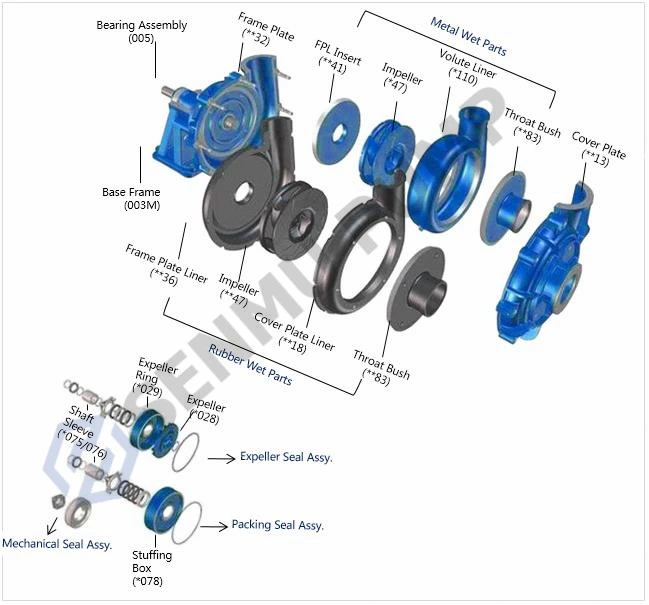

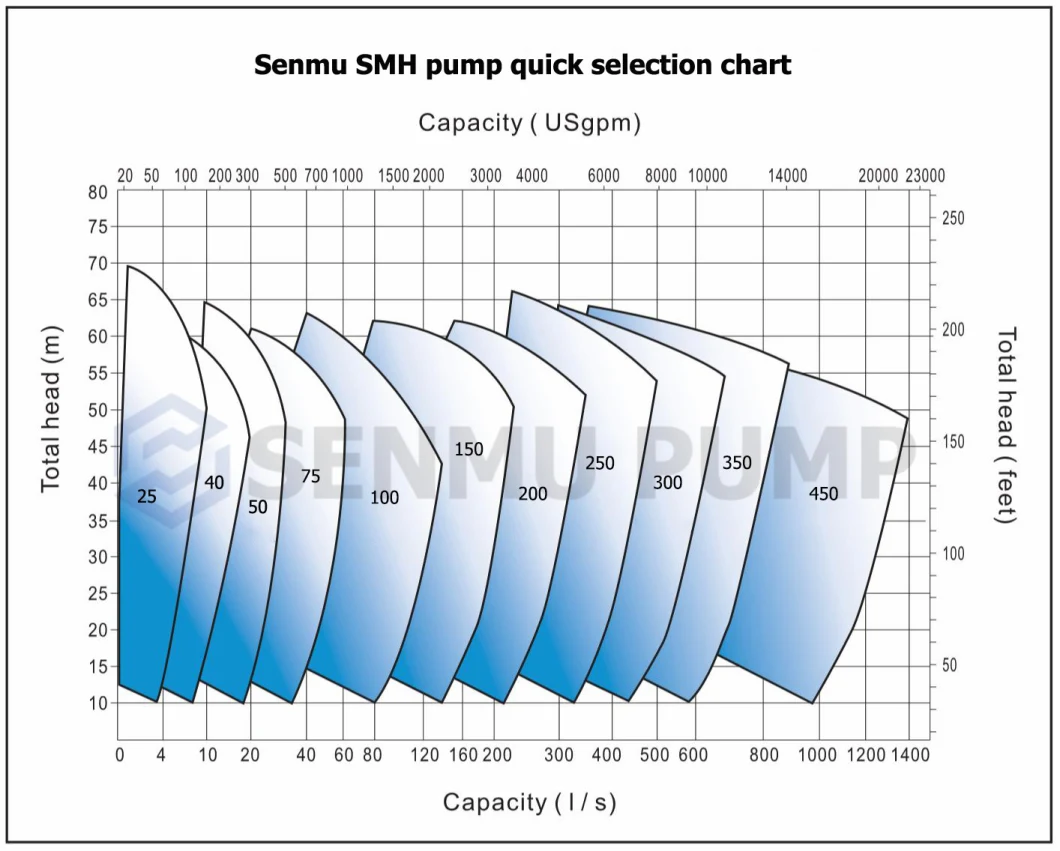

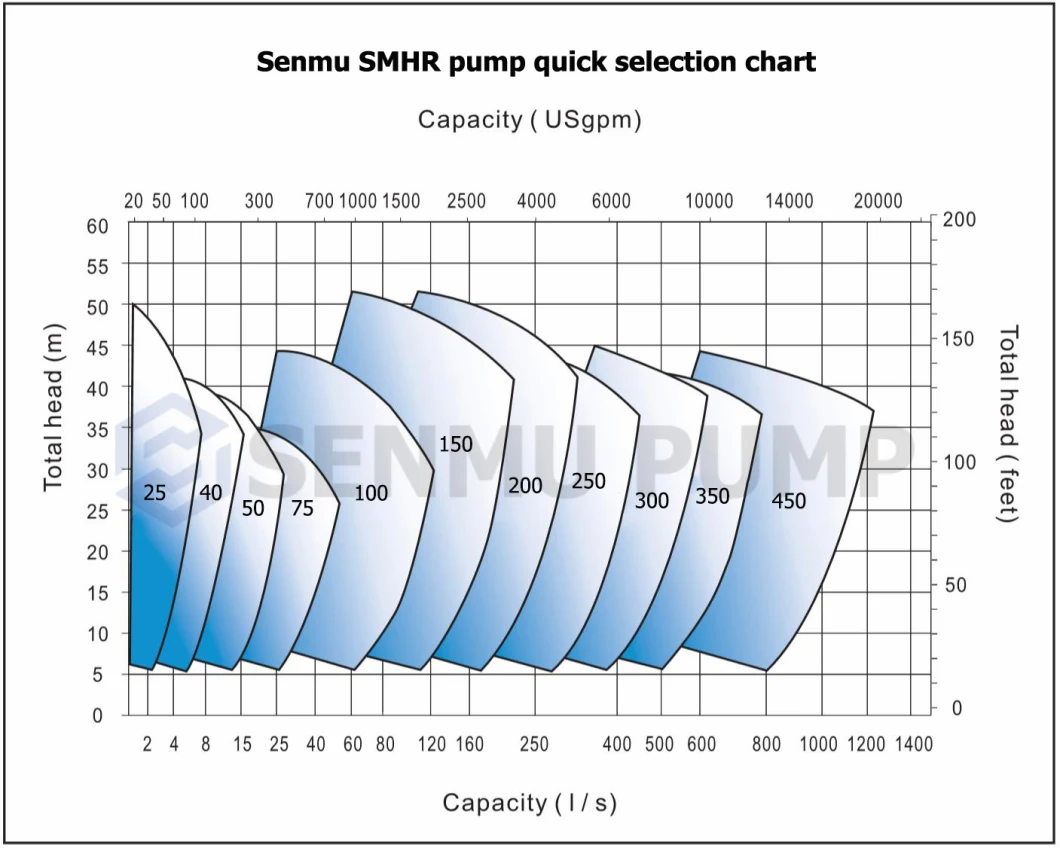

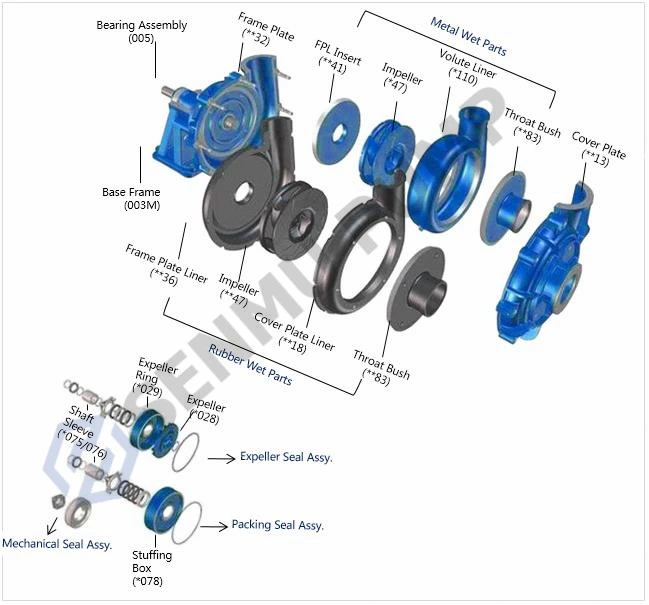

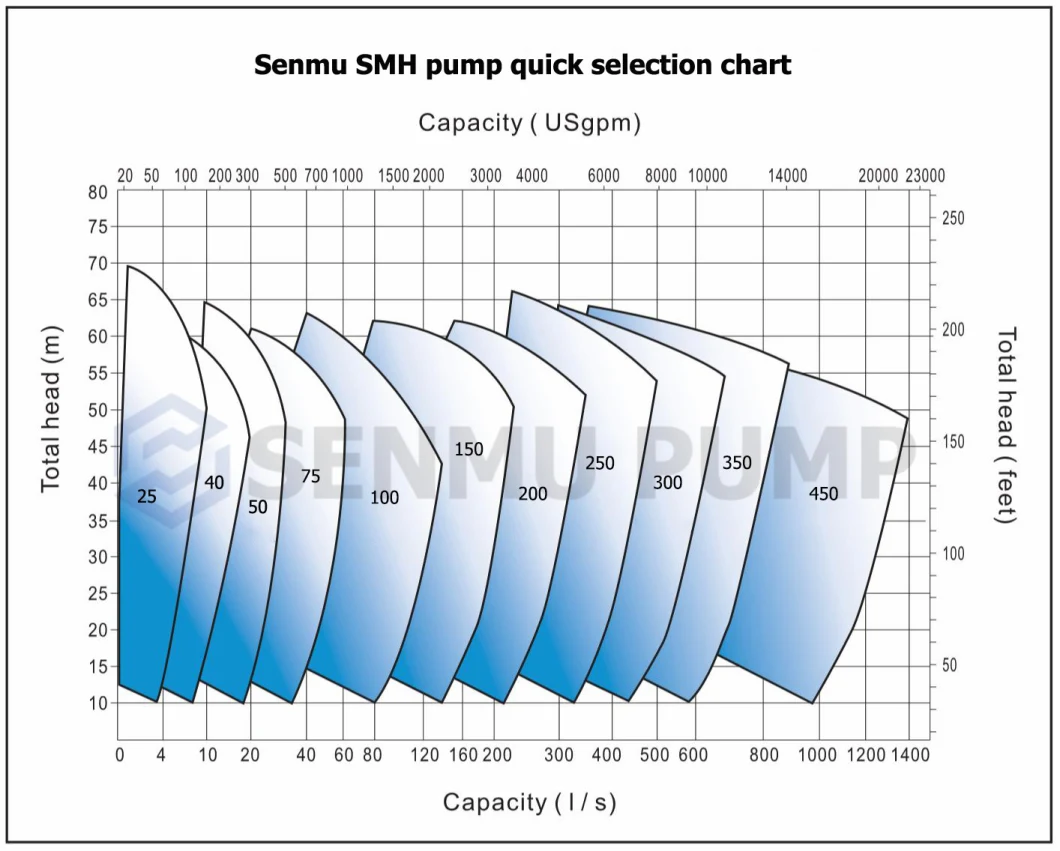

SMH(R) pumps are designed for the continuous pumping of highly abrasive, high density slurries with minimal maintenance requirements bolts reduce maintenance and minimize downtime, the horizontal centrifugal pumps will maintain high efficiencies over the wear life of its components. Rubber lined pumps expand application to chemical slurries handling, several different rubber options are available to meet different application need.

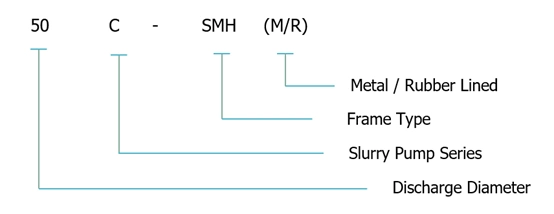

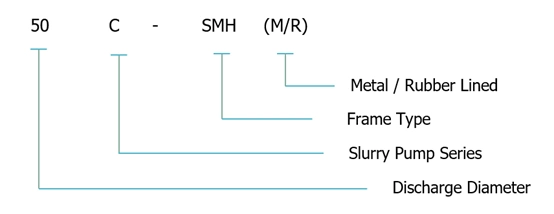

1.2 Notation:

For example:

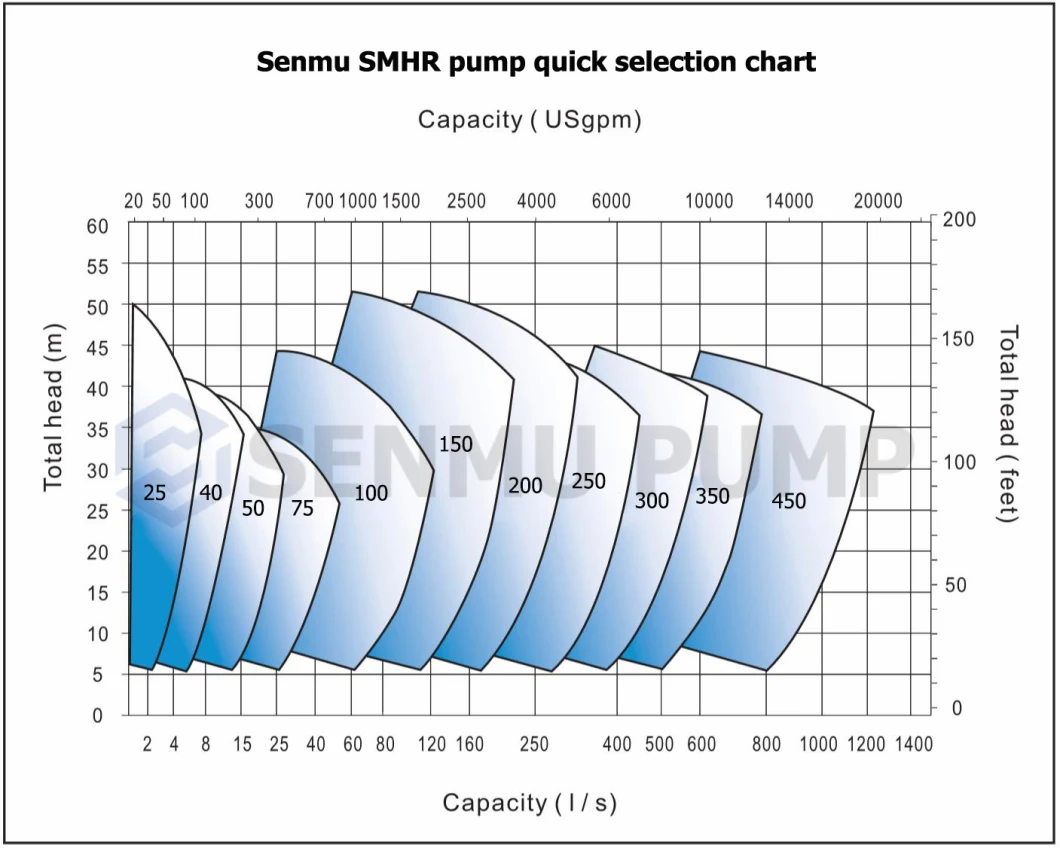

1.3 Application:

1.4:

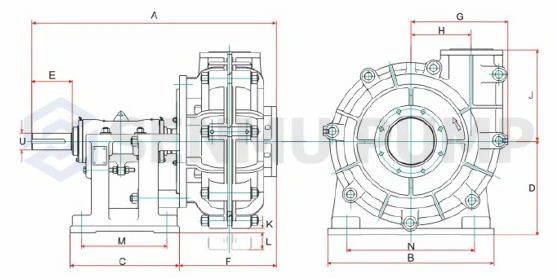

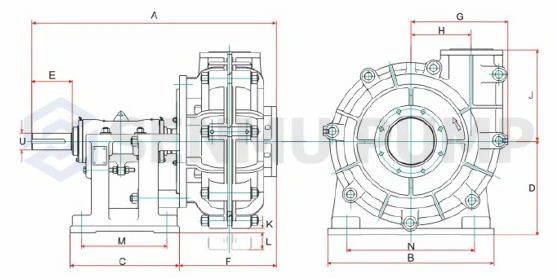

1.5 Outline Dimensions:

SMH(R) pumps are designed for the continuous pumping of highly abrasive, high density slurries with minimal maintenance requirements bolts reduce maintenance and minimize downtime, the horizontal centrifugal pumps will maintain high efficiencies over the wear life of its components. Rubber lined pumps expand application to chemical slurries handling, several different rubber options are available to meet different application need.

1.2 Notation:

For example:

1.3 Application:

- Heavy Minerals

- Mill Discharge

- Coal Washing

- Cyclone Feed

- Power Plant

- Chemical Process

- Paper and Pulp

- Sugar Beet

- Diamond Concentrate

- Thickener Overflow

- Slag Granulation

- Tailings

- Palm Oil Expression

- Plant Water Supply

1.4:

| Model | Max. Motor Power Kw | Material | Clear Water Performance | Impel. | ||||||

| Capacity Q | Head | Pump Speed | Max. Eff. | NPSH | Dia. | |||||

| Liner | Impel. | (m³/hr) | (l/s) | H(m) | n(r/min) | η% | (m) | (mm) | ||

| 25B-SMH | 15 | M | M | 12.6-28.8 | 3.5-8 | 6-68 | 1200-3800 | 40 | 2-4 | 152 |

| 25B-SMHR | RU | RU | 10.8-25.2 | 3-7 | 7-52 | 1400-3400 | 35 | |||

| 25C-SMHH | 30 | M | M | 16.2-34.2 | 4.5-9.5 | 25-92 | 1400-2200 | 20 | 2-5.5 | 330 |

| 40B-SMH | 15 | M | M | 32.4-72 | 9-20 | 6-58 | 1200-3200 | 45 | 3.5-8 | 184 |

| 40B-SMHR | RU | RU | 25.2-54 | 7-15 | 5.5-41 | 1000-2600 | 50 | 2.5-5 | 178 | |

| 50C-SMH | 30 | M | M | 39.6-86.4 | 11-24 | 12-64 | 1300-2700 | 55 | 4-6 | 214 |

| 50C-SMHR | RU | RU | 36-75.6 | 10-21 | 13-46 | 1300-2300 | 60 | 2-4 | 213 | |

| 50D-SMHH | 60 | M | M | 68.4-136.8 | 19-38 | 25-87 | 850-1400 | 47 | 3-7.5 | 457 |

| 75C-SMH | 30 | M | M | 86.4-198 | 24-55 | 9-52 | 1000-2200 | 71 | 4-6 | 245 |

| 75D-SMH | 60 | |||||||||

| 75C-SMHR | 30 | RU | RU | 79.2-180 | 22-50 | 5-34.5 | 800-1800 | 59 | 3-5 | 245 |

| 75D-SMHR | 60 | |||||||||

| 75E-SMHH | 120 | M | M | 126-252 | 35-70 | 12-97 | 600-1400 | 50 | 2-5 | 508 |

| 100D-SMH | 60 | M | M | 162-360 | 45-100 | 12-56 | 800-1550 | 65 | 5-8 | 365 |

| 100E-SMH | 120 | |||||||||

| 100D-SMHR | 60 | RU | RU | 144-324 | 40-90 | 12-45 | 800-1350 | 65 | 3-5 | 365 |

| 100E-SMHR | 120 | |||||||||

| 100F-SMHH | 260 | M | M | 324-720 | 90-200 | 30-118 | 600-1000 | 64 | 3-8 | 711 |

| 150S-SMHH | 560 | M | M | 468-1008 | 130-280 | 20-94 | 500-1000 | 65 | 4-12 | 711 |

| 150E-SMH | 120 | M | M | 360-828 | 100-230 | 10-61 | 500-1140 | 72 | 2-9 | 510 |

| 150R-SMH | 300 | |||||||||

| 150E-SMHR | 120 | RU | RU | 32-720 | 90-200 | 7-49 | 400-1000 | 65 | 5-10 | 510 |

| 150R-SMHR | 300 | |||||||||

| 200ST-SMH | 560 | M | M | 612-1368 | 170-380 | 11-61 | 400-850 | 71 | 4-10 | 686 |

| 200ST-SMHR | RU | RU | 540-1188 | 150-330 | 12-50 | 400-750 | 75 | 4-12 | ||

| 200E-SMM | 120 | M | M | 540-1440 | 150-400 | 14-60 | 600-1000 | 73 | 4-10 | 549 |

| 200R-SMM | 300 | |||||||||

| 250ST-SMH | 560 | M | M | 936-1980 | 260-550 | 7-68 | 330-800 | 82 | 6 | 762 |

| 250ST-SMHR | RU | RU | 720-1620 | 200-450 | 7-45 | 300-650 | 80 | 2.5-7.5 | ||

| 300ST-SMH | 560 | M | M | 1260-2772 | 350-770 | 13-63 | 300-600 | 77 | 3-10 | 965 |

| 300ST-SMHR | RU | RU | 1152-2520 | 320-700 | 13-44 | 300-500 | 79 | 3-8 | ||

| 350TU-SMH | 1200 | M | M | 1368-3060 | 380-850 | 11-63 | 250-550 | 79 | 4-10 | 1067 |

| 400TU-SMH | 1200 | M | M | 2160-5054 | 600-1400 | 8-66 | 200-500 | 80 | 4.5-9 | 1245 |

| 450TU-SMH | 1200 | M | M | 2520-5400 | 700-1500 | 13-57 | 200-400 | 85 | 5-10 | 1370 |

1.5 Outline Dimensions:

| Model | A | B | C | D | U | E | F | G | H | J | K | L | M | N | Weight(kg) | |

| Metal | Rubber | |||||||||||||||

| 25B-SMH(R) | 583 | 295 | 248 | 197 | 28 | 79 | 206 | 181 | 98 | 171 | 46 | - | 143 | 254 | 91 | 77 |

| 25C-SMHH | 759 | 406 | 311 | 254 | 42 | 121 | 306 | 270 | 194 | 254 | - | 11 | 175 | 356 | 318 | - |

| 40B-SMH(R) | 592 | 295 | 248 | 197 | 28 | 79 | 217 | 205 | 114 | 184 | 33 | - | 143 | 254 | 104 | 118 |

| 50C-SMH(R) | 768 | 406 | 311 | 254 | 42 | 121 | 281 | 238 | 138 | 210 | 71 | - | 175 | 356 | 191 | 154 |

| 50D-SMHH | 986 | 492 | 364 | 330 | 65 | 164 | 389 | 384 | 254 | 368 | - | 51 | 213 | 432 | 750 | - |

| 75C--SMH(R) | 834 | 406 | 311 | 254 | 42 | 121 | 354 | 292 | 149 | 262 | 24 | - | 175 | 356 | 263 | 236 |

| 75D--SMH(R) | 943 | 492 | 364 | 330 | 65 | 164 | 353 | 292 | 149 | 262 | 100 | - | 213 | 432 | 363 | 290 |

| 75E-SMHH | 1240 | 622 | 448 | 457 | 80 | 222 | 492 | 492 | 330 | 432 | - | - | 257 | 546 | 1250 | - |

| 100D-SMH(R) | 1021 | 492 | 364 | 330 | 65 | 164 | 421 | 406 | 229 | 338 | 11 | - | 213 | 432 | 626 | 454 |

| 100E-SMH(R) | 1178 | 622 | 448 | 457 | 80 | 222 | 433 | 406 | 229 | 338 | 138 | - | 257 | 546 | 728 | 635 |

| 150S-SMHH | 1998 | 920 | 780 | 450 | 120 | 280 | 596 | 616 | 413 | 546 | - | 134 | 640 | 760 | 2880 | - |

| 150E-SMH(R) | 1302 | 622 | 448 | 457 | 80 | 222 | 557 | 551 | 318 | 460 | - | 62 | 257 | 546 | 1473 | 982 |

| 150R-SMH(R) | 1360 | 680 | 590 | 350 | 85 | 215 | - | 511 | 318 | 460 | - | 170 | 490 | 560 | 1655 | 1164 |

| 150T-SMHH | 2275 | 1150 | 1040 | 650 | 150 | 350 | 852 | 835 | 584 | 813 | - | 160 | 880 | 900 | 6586 | - |

| 200E-SMM | 1337 | 622 | 448 | 457 | 80 | 222 | 584 | 613 | 381 | 470 | - | 83 | 257 | 546 | 1625 | 1202 |

| 200R-SMM | 1395 | 680 | 590 | 350 | 85 | 215 | - | 613 | 381 | 470 | - | 190 | 490 | 560 | 1836 | - |

| 200ST-SMH(R) | 1748 | 1150 | 780 | 650 | 120 | 280 | 692 | 673 | 419 | 635 | 27 | - | 620 | 900 | 3750 | 3130 |