1.Product Description

WQ/QW non-clog submersible sewage pump/drainage pump (hereinafter called "pump") is integrative motor and pump. Which is manufactured based on absorbing domestic and foreign advanced technology and advantages. Impeller, designed with hydraulic model and made by precision casting, has the advantages of energy-saving, anti-winding and non-clogging, etc. At the same time, this sewage pump has a unique effect in the carriage of solid particles and long fibers garbage. Single or dual impellor structure ensures the sewage pump has the higher efficiency when it has bigger flow. So this kind of sewage pump is an ideal drainage pumps for industries and cities.

2.Operating Conditions

1. Capacity scope: 2~6000 m³/h;

2. System pressure: ≤0.6mpa;

3. Medium consistency: ≤1.3×10³kg/m³;

4. Motor insulation class: IP68;

5. Rotation: clockwise rotation viewed from motor;

6. Rated Speed: 970-2900r/min;

7. Head scope: 3-45;

8. Medium temperature: -15°C~+100°C;

9. Medium PH scope: 5-9;

10. Motor insulation class: E Grade;

3.Pump Material

| Structure of pump | Material | Can be selected |

| Pump body | Cast-Iron | Stainless steel |

| Impeller | Cast-Iron | Stainless Steel |

| Pump shaft | 45 # Steel | Stainless steel |

Cable | Arbitrary length | |

4.Model Technical Parameters(More Information Pls Don't Hesitate To Contact Us)

| Appellation | Model | Flow | Head (m) | Power (kW) | HP | Voltage (V) | Velocity (r/min) | Pipe size | ||

| m³/h | l/min | mm | Inch | |||||||

WQ Non-Clogging Sewage Submersible Pump | WQ10-10-0.75 | 10 | 166.7 | 10 | 0.75 | 1 | 220/380 | 2860/3000 | 50 | 2 |

| WQ15-10-1.1 | 15 | 250 | 10 | 1.1 | 1.5 | 50 | 2 | |||

| WQ15-15-1.5 | 15 | 250 | 15 | 1.5 | 2 | 50/63 | 2/2.5 | |||

| WQ16-18-2.2 | 16 | 267 | 18 | 2.2 | 3 | 380 | 3000 | 50 | 2 | |

| WQ16-18-2.2 | 16 | 267 | 18 | 2.2 | 3 | 50 | 2 | |||

| WQ15-30-3 | 15 | 250 | 30 | 3 | 4 | 50 | 2 | |||

| WQ25-17-3 | 25 | 417 | 17 | 3 | 4 | 75 | 3 | |||

| WQ15-36-4 | 15 | 250 | 36 | 4 | 5.5 | 65 | 2.5 | |||

| WQ60-10-4 | 60 | 1000 | 10 | 4 | 5.5 | 100 | 4 | |||

| WQ30-20-5.5 | 30 | 500 | 20 | 5.5 | 7.5 | 75 | 3 | |||

| WQ55-15-5.5 | 55 | 917 | 15 | 5.5 | 7.5 | 100 | 4 | |||

| WQ45-22-7.5 | 45 | 750 | 22 | 7.5 | 10 | 100 | 4 | |||

| WQ100-10-7.5 | 100 | 1667 | 10 | 7.5 | 10 | 150 | 6 | |||

| WQ100-15-11 | 100 | 1667 | 15 | 11 | 15 | 1450 | 100 | 4 | ||

| WQ140-10-11 | 140 | 2333 | 10 | 11 | 15 | 150 | 6 | |||

| WQ130-15-11 | 130 | 2167 | 15 | 11 | 15 | 150 | 6 | |||

| WQ300-7-15 | 300 | 500 | 7 | 15 | 20 | 150 | 8 | |||

| WQ200-10-15 | 200 | 3334 | 10 | 15 | 20 | 150 | 6 | |||

| WQ100-20-15 | 100 | 1667 | 20 | 15 | 20 | 100 | 4 | |||

| WQ180-15-15 | 180 | 3000 | 15 | 15 | 20 | 150 | 6 | |||

| WQ250-11-15 | 250 | 4167 | 11 | 15 | 20 | 200 | 8 | |||

| WQ100-22-18.5 | 100 | 1667 | 22 | 18.5 | 25 | 100 | 4 | |||

| WQ140-15-18.5 | 140 | 2333 | 15 | 18.5 | 25 | 150 | 6 | |||

| WQ200-12-18.5 | 200 | 3334 | 12 | 18.5 | 25 | 200 | 8 | |||

| WQ100-30-22 | 100 | 1667 | 30 | 22 | 30 | 100 | 4 | |||

| WQ300-10-22 | 300 | 5000 | 10 | 22 | 30 | 150 | 6 | |||

| WQ400-7-22 | 400 | 6667 | 7 | 22 | 30 | 200 | 8 | |||

| WQ180-30-30 | 180 | 3000 | 30 | 30 | 40 | 150 | 6 | |||

| WQ250-22-30 | 250 | 4167 | 22 | 30 | 40 | 200 | 8 | |||

| WQ600-9-30 | 600 | 10000 | 9 | 30 | 40 | 250 | 10 | |||

| WQ900-7-30 | 900 | 15000 | 7 | 30 | 40 | 300 | 12 | |||

| WQ180-37-37 | 180 | 3000 | 37 | 37 | 50 | 1000 | 150 | 6 | ||

| WQ350-25-37 | 350 | 5833 | 25 | 37 | 50 | 200 | 8 | |||

| WQ600-12-37 | 600 | 10000 | 12 | 37 | 50 | 250 | 10 | |||

| WQ900-8-37 | 900 | 15000 | 8 | 37 | 50 | 300 | 12 | |||

| WQ180-45-45 | 180 | 3000 | 45 | 45 | 60 | 150 | 6 | |||

| WQ400-25-45 | 400 | 6667 | 25 | 45 | 60 | 200 | 8 | |||

| WQ600-15-45 | 600 | 10000 | 15 | 45 | 60 | 250 | 10 | |||

| WQ800-12-45 | 800 | 13333 | 12 | 45 | 60 | 300 | 12 | |||

| WQ400-30-55 | 400 | 6667 | 30 | 55 | 75 | 200 | 8 | |||

| WQ600-20-55 | 600 | 10000 | 20 | 55 | 75 | 250 | 10 | |||

| WQ800-15-55 | 800 | 13333 | 15 | 55 | 75 | 300 | 12 | |||

| WQ350-40-75 | 350 | 5833 | 40 | 75 | 100 | 200 | 8 | |||

| WQ600-25-75 | 600 | 10000 | 25 | 75 | 100 | 250 | 10 | |||

| WQ800-20-75 | 800 | 13333 | 20 | 75 | 100 | 300 | 12 | |||

| WQ400-45-90 | 400 | 6667 | 45 | 90 | 120 | 200 | 8 | |||

| WQ600-30-90 | 600 | 10000 | 30 | 90 | 120 | 250 | 10 | |||

| WQ950-20-90 | 950 | 15833 | 20 | 90 | 120 | 300 | 12 | |||

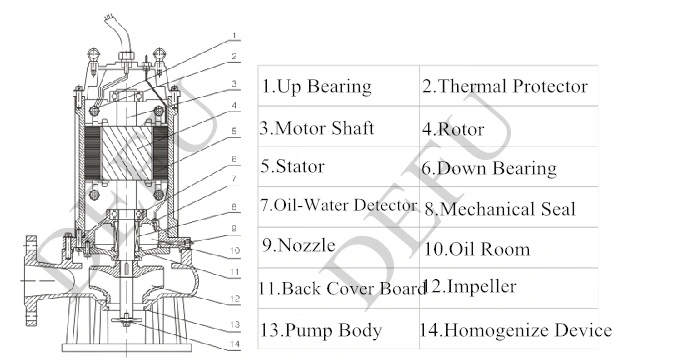

5.Pump Structures

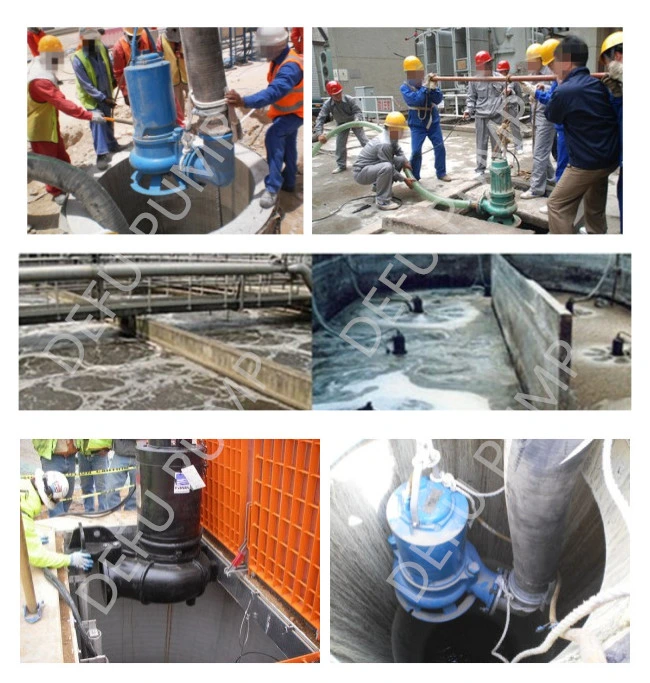

6.Applications Show(From Our Clients)

7.Our Services

1. Delivery: Delivery time will be on time as the contract. Usually, our company need 10 working days for cast iron submersible pump,30 days for stainless steel submersible pump.

2. Warranty: 12 month for the pump body, 3 month for the main working parts.

3. Package: We use plywood case to pack our pump, which is durable for ocean transport.

4. On-sales Service: we will clear show you everything in fact when you place an order with us. We will take photos or videos to show you our production situation, and report the production situation to you.

5. Quality: we will test our pump before delivery, and we will follow up the pump working conditions per three months when the pump put into use. If you need spare parts, we can send to you in 1 or 2 weeks.

8.Our fatory

Welcome to visit our factory!

All My Striving,For Your Satisfaction.

*********************************************************************************************

Head Office: Wenzhou DEFU Machinery Co.,Ltd

Subsidiary Factory Name:Shanghai Y&L Pump Co.,Ltd

Mobile :+86 -18042130095 Fax: +86-577-86553150

WebSite:defucc-machinery.en.made-in-china.com