Electrical Non Clogging Submersible Sewage Drainage Axial Mix Flow Slurry Centrifugal Water Pump

This series pump with adjustable impellers has the advantages of large capacity,broad head, high efficiency, wide application and so on.

A:pump station is small in scale, the construction is simple and the investment is greatly decreased, This can save 30%~ 40% for the building cost.

B: It is easy to install maintain and repair this kind of pump.

C: low noise long life.

The material of the series of MVS AVS can be casting ductile iron copper or stainless steel.

| Diameter | DN350-1400 mm |

| Capacity | 900-12500 m3/h |

| Head | up to 20m |

| Liquid Temperature | up to 50 ºC |

ACCESSORIES FOR PUMP

1.Sewage Grid

2.Flag valve

3.Pre-buried pipe

4.Water Level Switch

5. Control panel

Installation type

AVS/ MVS Axial flow and Mixed flow submersible pumps are suitable for elbow cantilever installation, well cantilever installation and concrete well cantilever installation

Installation of Suction and Discharge Pipes

1.Suction Pipe: according to the outline drawing in the booklet. The smallest depth of the pump under the water should be bigger than the datum in the drawing.

2.Discharge:flap valve and other methods.

3.Installation: MVS series are suitable for elbow cantilever installation, well cantilever installation and concrete well cantilever installation.

Motor

Submersible Motor(MVS series) Power class: electric performance meets GB755

Protection class:IP68

Cooling system:ICWO8A41

Basic installation type: IM3013

Voltage: up to 355kw, 380V 600V 355KW, 380V 600V ,6kv, 10kv

Insulation class: F

Rated power: 50Hz

Length of cable: 10m

Shaft Seal

This type has two or three mechanical seals. The first seal, which contacts water, is usually made of carbon silicon and carbon silicon. The second and third are usually made of graphite and carbon silicon.

Leakage Protection

MVS AVS series has leakage protection sensor. When the oil house of motor or the wire-box is leaking, sensor will give out warning or stop working and maintain the signal.

Overheat Protector

The winding of MVS series submersible motor has overheat protector. When it is overheated, warning will be given out or the motor will stop working.

Rotating Direction

Looking from upper side, the impeller is rotating clockwise.

Series Definition

MVS series axial-flow pumps AVS series mixed-flow pumps (Vertical Axial flow and Mixed flow submersible sewage pump) are modern productions successfully designed by the means of adopting foreign modern technology. The new pumps' capacity are 20%larger than the old ones. The efficiency is 3~5% higher than the old ones.

With adjustable impellers has the advantages of large capacity / broad head / high efficiency / wide application and so on.

A:pump station is small in scale, the construction is simple and the investment is greatly decreased, This can save 30%~ 40% for the building cost.

B: It is easy to install maintain and repair this kind of pump.

C: Low noise long life.

The material of the series of AVS/ MVS Axial flow and Mixed flow submersible pump can be casting ductile iron copper or stainless steel.

a) Industry & agriculture

b) Water supply for cities

c) Mild sewage drainage

d) Water transfer project

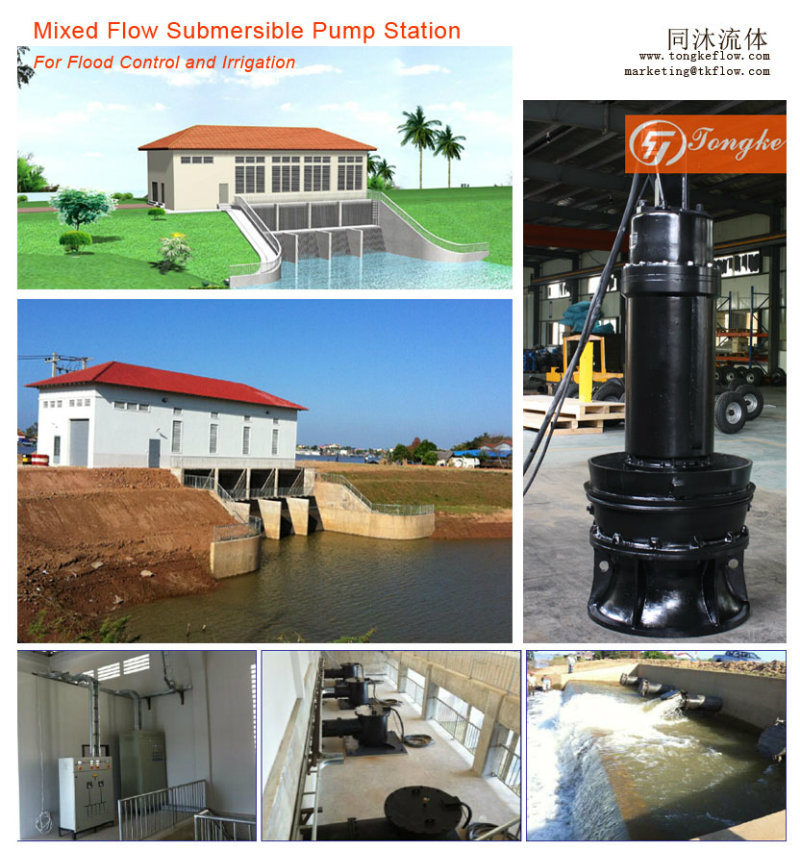

SAMPLE PROJECT

More details for AVS/ MVS Vertical Axial flow and Mixed flow submersible sewage pump please check with our engineer.